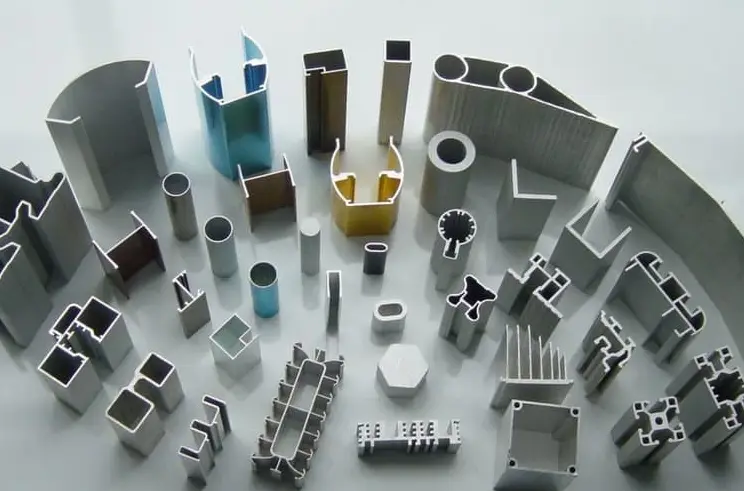

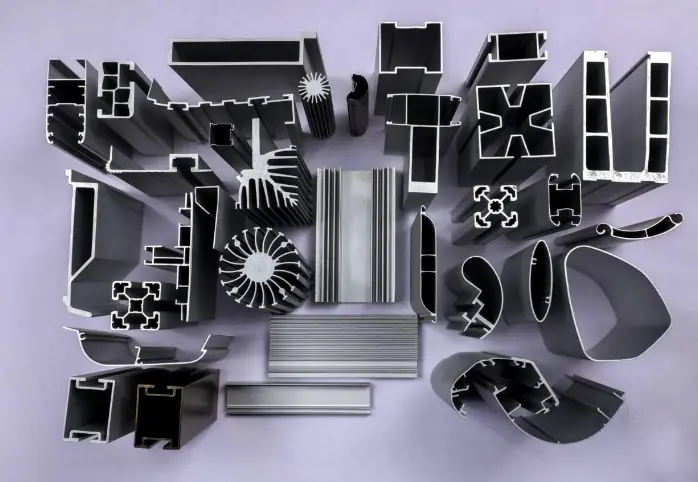

Aluminum extrusions serve in a very wide set of roles: they provide lightweight structural members, precision frames, thermal management parts, architectural profiles, and finished components for transport, electronics, energy, and consumer products. Their main strengths are high strength-to-weight ratio, corrosion resistance, excellent thermal conductivity, design flexibility, and efficient volume production. These traits make extruded aluminum the preferred choice when designers need custom cross-sections that combine performance, manufacturability, and cost control.

What is an aluminum extrusion

An aluminum extrusion is a metal profile made when heated aluminum billet is forced through a shaped steel die. The result is a continuous section with a consistent cross-section. Production can yield very simple shapes such as tubes and rods or complex profiles containing internal cavities and mounting ribs. The process produces tight dimensional control and repeatable geometry for long lengths.

Core properties that determine how extrusions are used

Short lists help match the property to typical roles.

Mechanical and physical strengths

-

High specific strength (strength divided by weight), good for light structural tasks.

-

Good fatigue resistance for repeated-load components.

-

Flexible in forming: complex sections with thin walls and stiffening ribs.

Environmental performance

-

Natural corrosion resistance due to oxide layer; extended life in outdoor settings.

-

Good recyclability; scrap aluminum retains value and can be re-fed to production.

Functional properties

-

Excellent thermal conductivity for heat sinks and thermal management.

-

Electrical conductivity useful for busbars and certain conductors.

-

Surface finishing options (anodizing, powder coat, plating) provide both protection and appearance.

These combined properties explain why extrusions appear in industries from buildings to electronics.

Major industries and common applications

Below is a compact mapping between industry and the typical roles extruded aluminum plays.

Architecture and building systems

-

Window and door frames, curtain wall mullions, handrails, balustrades, storefront systems, sunshades.

-

Benefit: weather resistance, aesthetic finish, long spans with lighter weight.

Transportation and automotive

-

Body panels, roof rails, bumper beams, battery housings for electric vehicles, structural frames for mass transit, trailer parts.

-

Benefit: reduce vehicle weight to improve fuel economy or range.

Electronics and electrical systems

-

Heat sinks for LED lighting and power electronics, electronic enclosures, busbars for switchgear.

-

Benefit: high thermal conductivity and easy fabrication into fins and channels.

Renewable energy and utility equipment

-

Solar panel frames, racking systems, inverter housings, cable trays, telecom towers.

-

Benefit: corrosion resistance in outdoor installations and low maintenance.

Industrial automation and manufacturing equipment

-

Machine frames, t-slot modular workstations, conveyor rails, safety guards, cleanroom structures.

-

Benefit: modular assembly, repeatable tolerances, quick reconfiguration.

Aerospace and defense

-

Structural extrusions for cabin, cargo handling rails, mounting brackets, thermal conduction components.

-

Benefit: strict weight budgets and tight dimensional control for long-length parts.

Consumer goods and furniture

-

Lighting trims, appliance frames, shelving, furniture framing, sporting goods.

-

Benefit: good finish quality and pleasant feel for visible components.

Three quick tables

Table 1 Industry ⇢ Typical extrusion roles

| Industry | Typical extrusion roles |

|---|---|

| Architecture & construction | Window frames, curtain walls, railings, louvers |

| Automotive & transport | Crash management sections, battery enclosures, extruded chassis rails |

| Electronics & electrical | Heat sinks, enclosures, busbars |

| Energy | Solar racking, transformer housings, cable trays |

| Industrial manufacturing | Machine frames, t-slot systems, guards |

| Aerospace | Lightweight structural sections, interior frames |

(Sources: industry references and suppliers.)

Table 2 Common alloys and why they matter

| Alloy family | Typical grades | Why chosen |

|---|---|---|

| 6000 series | 6061, 6063 | Good extrudability, good finishing, general-purpose structural |

| 7000 series | 7075 | High strength when needed (often forged or heat treated) |

| 1000/3000 series | 1100, 3003 | High corrosion resistance, good for decorative/architectural pieces |

| Specialty | 6060, 6082 | Optimized for certain profiles, tradeoff between strength and extrusion ease |

(Choice depends on mechanical needs, finishing, and welding requirements.)

Table 3 Production step quick reference

| Step | What happens | Designer tip |

|---|---|---|

| Billet prep | Aluminum billet heated to extrusion temp | Know max alloy temperature limits |

| Die pressing | Billet forced through die under pressure | Account for die swell and tolerances |

| Stretching | Profile straightened and tensioned | Longer profiles need controlled cooling |

| Aging/heat treatment | Sets mechanical properties | Specify temper in part drawings |

| Finishing | Anodize, paint, machining | Plan secondary operations into cost |

Design considerations that determine whether to use extrusions

If you are choosing a manufacturing route, test these rules-of-thumb.

-

Choose extrusion when a repeated cross-sectional shape across long length is required.

-

Use extrusions when integrated features (snap fits, channels, ribs) will reduce secondary assembly.

-

Pick alloy and temper for either weldability or strength-first design.

-

Avoid extrusion if the part needs highly variable cross-sections along its length; then cast or machine may be better.

-

Factor in tooling cost: a custom die is an investment; unit price drops when volume is high.

These points explain why extrusions often sit at the center of design-for-manufacture decisions.

Thermal management and electrical roles (why heat sinks and busbars use extrusions)

Heat sinks and thermal fins

Extruded profiles can include many thin fins and wide surface area per unit volume. That geometry raises heat transfer efficiency while keeping mass low. For LED fixtures, power electronics, telecom racks, and inverter housings, extruded heat-sink sections combine thermal performance with straightforward mounting features.

Conductive electrical busbars

When designers need a rigid, conductive busbar for switchgear, the extrusion process produces solid or hollow conducting shapes that are easy to mount and cool. The combination of conductivity and mechanical form makes extrusions a favored choice in power distribution equipment.

Cost drivers and when extrusions win on price

Primary cost factors:

-

Die cost (one-time, tied to complexity).

-

Material cost per kilogram.

-

Secondary operations: cutting, machining, heat treatment, finishing.

-

Production volume. High volume spreads die cost. For mid-to-high production runs that require complex cross-sections, extrusions typically beat machining from solid or multi-piece welded assemblies.

Designers often reduce total system cost by folding multiple functions into one extruded profile: mounting flange, channel, and sealing groove can appear in a single part, cutting assembly time downstream.

Surface finishes and corrosion protection

Common finishes:

-

Anodizing — durable oxide layer that improves surface hardness and decorative options.

-

Powder coating — thick finishes for color and protection.

-

Mechanical polishing or brushing for premium aesthetics.

-

Chromate conversion coatings for improved paint adhesion.

Selecting finish depends on exposure environment and visual goals. For architectural facades, anodize provides a long-lasting look; for industrial frames, powder coat may offer better color variety and repairability.

Typical part tolerances and lengths

-

Standard extruded lengths run from a few feet up to 8–12 meters, depending on mill capability and handling.

-

Dimensional tolerances depend on profile complexity and wall thickness; designers use published extruder tolerance tables early in the CAD phase.

-

Thin walls (<1.0 mm) are possible but require careful alloy and die design.

Quick checklist for specifying extrusions

-

Define functional cross-section and list integrated features.

-

Pick alloy and temper based on strength, weldability, and finishing needs.

-

Provide profile sketch, tolerances, and finish requirements.

-

Estimate annual volume and length to help supplier evaluate die amortization.

-

Decide secondary operations the vendor should perform.

-

Include corrosion exposure class for finish selection.

Common myths and corrections

Myth: Extrusions are only for simple shapes.

Reality: Complex geometries, internal cavities, and thin webs are possible with modern tooling and process control.

Myth: Extrusions always cost less than casting.

Reality: For low volume or highly three-dimensional forms, casting or machining can be cheaper. Tooling and volume determine the winner.

Myth: Aluminum cannot be strong enough for structural jobs.

Reality: Many alloys and heat treatments yield strength levels fit for trailers, railings, and even certain aircraft parts when engineered correctly.

How extrusions compare to other manufacturing routes

Extrusion vs casting

-

Extrusion: best for constant cross-section, long lengths, thinner walls.

-

Casting: best for complex 3D shapes with variable cross-sections.

Extrusion vs machining from billet

-

Extrusion: lower material waste, faster production for repeated cross-sections.

-

Machining: better for single, highly complex parts or small runs without die cost.

Extrusion vs stamping/folding sheet

-

Extrusion: stronger cross-section and integrated features.

-

Sheet metal: cheaper for flat parts and highly variable shapes.

Environmental and regulatory aspects

Aluminum recycling is energy-efficient because recycled aluminum needs far less energy than primary production. Many building codes and green building rating systems prize recycled content and material longevity. Using extruded aluminum with high recycled content supports sustainability goals for products and structures.

FAQs

1. What is the most common use of extruded aluminum?

Extruded aluminum most often appears in architectural framing and industrial framing. Window and door systems, curtain walls, and modular machine frames are repeated high-volume uses because the profile can combine structural support with weather seals and mounting features in one part.

2. Which aluminum alloy works best for extrusions?

6063 and 6061 are common general-purpose alloys. 6063 gives very good surface finish and is preferred for architectural work. 6061 provides higher strength for structural needs. For extremely high-strength parts, 7000-series alloys or hybrid solutions may be chosen with additional processing.

3. Can extrusions be welded and machined after forming?

Yes. Many alloys join well by TIG or MIG processes. Machine operations like drilling, tapping, and milling are routine. Secondary machining is often specified to achieve final mounting interfaces or precision holes. Inform the supplier which operations you want performed to include cost in the quote.

4. What are typical lead times and cost drivers?

Lead time depends on die design, finish, and volume. Tooling design and die manufacture can take weeks. For mature profiles with existing dies, lead times drop significantly. Unit cost falls steeply as volume grows, due to die amortization and production efficiency.

5. Are extrusions durable outdoors?

Yes. With proper alloy and finish (anodize or powder coat), extrusions perform well in outdoor environments for decades while requiring low maintenance. Design details such as drainage and thermal movement must be considered in façade and glazing systems.

Final checklist before ordering

-

Confirm final cross-section CAD, dimension tolerances, and profile length.

-

Choose alloy and temper.

-

Schedule secondary operations and final finish.

-

Request sample piece and pull test or structural validation if needed.

-

Ask supplier for production tolerances and straightening method for long lengths.

Closing summary

Aluminum extrusions are a versatile manufacturing solution for many industries. They blend performance traits—low weight, corrosion resistance, thermal conductivity, and design flexibility—with efficient production when repeated cross-sections are needed. Use extrusions to reduce assembly steps, improve product durability, and hit weight targets for transport and energy-sensitive systems. Pair smart design with the correct alloy and finish, and an extrusion solution will often outperform alternatives in cost and long-term performance.