For most industrial framing, machine guarding, automation, and rapid-prototyping needs, YouHeng’s T slot aluminum extrusion profiles made from high-grade 6000-series alloy strike the strongest balance between weight, corrosion resistance, and modular flexibility. For light fixtures and hobby builds, choose 20 mm series; for general-purpose workstations and mid-load automation, choose 30 mm and 40 mm series; for heavy gantries and industrial automation, choose 45 mm, 60 mm, or custom large sections. These choices reduce total system weight, shorten build time, and lower long term maintenance costs.

Why T slot aluminum extrusion profiles matter for modern fabrication

T slot extrusions provide a repeatable, modular structural system that removes the need for bespoke welding in many applications. The continuous slot that runs the extrusion length accepts T-nuts and fasteners, enabling simple repositioning of components and panel attachments. This modularity boosts productivity for production line changes and short production runs. Major suppliers and system houses highlight machine frames, safety guards, workstations, and automation supports as primary applications.

Key advantages summarized

- Lightweight strength: high strength to weight ratio reduces foundation and transport costs.

- Corrosion resistance: natural oxide layer on aluminum reduces corrosion risks in factory and lab settings.

- Tool-friendly: profiles cut, machined, tapped, and milled using common shop tools.

- Fast assembly: T-nuts enable dry-fit assembly with repeatable repositioning.

- Aesthetic finish: anodized or painted surfaces provide a professional look for public-facing equipment.

Core technical parameters and standard series

Below is a compact reference for common metric series. Use this table when planning loads and compatibility with standard fasteners.

| Series name | Typical cross size mm | Common slot width mm | Typical alloy | Typical wall thickness mm |

|---|---|---|---|---|

| 20 series | 20 × 20 | 6 | 6063-T6 / 6063-T4 | 1.5–2.0 |

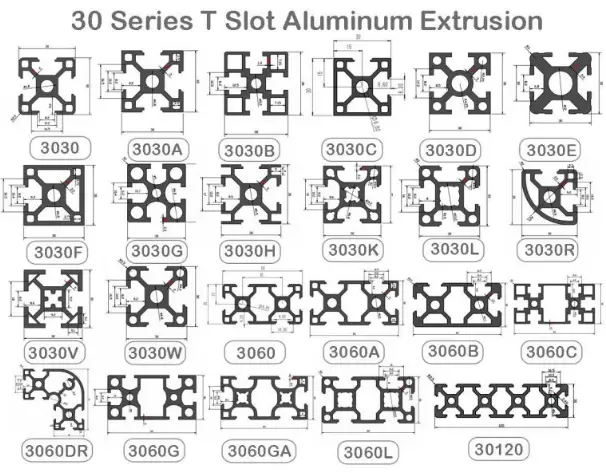

| 30 series | 30 × 30 | 8 | 6063-T6 | 1.8–2.5 |

| 40 series | 40 × 40 | 8–10 | 6063-T6 | 2.0–3.0 |

| 45 series | 45 × 45 | 10 | 6063-T6 | 2.5–3.5 |

| 60 series | 60 × 60 | 10–12 | 6063-T6 | 3.0–4.0 |

Reference vendor catalogs and metric spec pages for precise tolerances. Metric series and inch series overlap, but verify compatibility before ordering.

Common alloys and what they mean for performance

YouHeng recommends 6000-series aluminum for most profile work. The most frequent grades in the market are 6063 and 6061. Their characteristics:

- 6063: optimized for extrusion, excellent surface finish, high corrosion resistance, good mechanical strength when heat treated. Widely used for T slot framing.

- 6061: higher strength, often used when additional mechanical performance is required. More common in structural parts than in framing with decorative finish.

Choose 6063 for modular frames that also require anodizing. Choose 6061 when peak tensile strength is a priority. When fatigue or impact loading exists, perform a structural check with engineering inputs.

Surface finishes and post processing

Table of common finishes and tradeoffs.

| Finish | Typical process | Visual result | Corrosion resistance | Use case |

|---|---|---|---|---|

| Mill finish | none | matte silver | moderate | internal frames |

| Clear anodize | electrochemical | bright metallic | high | lab, cleanroom |

| Hard anodize | thicker anodic layer | darker, harder | very high | wear surfaces |

| Powder coat | dry paint baked | colored finish | high if prepped | public-facing equipment |

| PVDF paint | liquid coating | glossy color | excellent outdoor | signage, outdoor kiosks |

Surface choice affects cost and lead time. For normal indoor factory use, clear anodize provides a durable and low-maintenance surface.

Accessories and fastening systems

The T slot system depends on a matched ecosystem of fasteners and accessories. Typical items:

- T-nuts: slide into slot, accept machine screws. Slot width determines nut type.

- Joining plates: quick rigid connections for corners.

- Corner brackets: low-cost right angle supports for light frames.

- Panel clamps: hold sheet metal or acrylic panels inside the frame.

- Linear rail mounts: allow integration of motion systems.

- Feet, casters, hinges, handles, and doors.

Match fastener dimensions to profile slot dimension to guarantee slip-fit and required shear capacity. Standard component kits from major suppliers reduce design time.

Design rules and best practices

Short, actionable rules that reduce rework.

- Plan for rigidity: use diagonal bracing or gusset plates for tall frames.

- Match series to load: pick a larger series when bending stiffness is critical.

- Use continuous rails: longer spans reduce the need for mid-supports.

- Pre-drill for precision: for repeated assembly, specify milled faces for accurate alignment.

- Avoid over-tightening T-nuts: aluminum threads can deform; consider steel inserts for repetitive assembly cycles.

- Document assembly sequence: modular systems become complex; clear instructions save hours.

When in doubt, prototype a small section to verify fit and clearance.

Manufacturing notes and tolerances

Extrusion begins with billet heating, die pushing, then tempering. Dies determine profile geometry and slot accuracy. Standard tolerances vary by supplier; for tight-machining work, specify milled faces or precision extrusions with ISO tolerance bands. If panels need absolute flatness, order profiles with milled reference faces. Many suppliers offer cut-to-length and machining services for single-source convenience.

Load performance and how to estimate it

Aluminum framing behavior under load depends on section modulus and span length. For simple beam loading:

- For a given span, stiffness increases with section height squared.

- Doubling profile section often reduces deflection by roughly fourfold for the same material.

Use vendor-generated calculators when available. Major framing vendors provide deflection calculators and recommended span limits for different series. For safety critical machinery, validate with a registered engineer.

Common industry applications by sector

| Industry | Typical uses |

|---|---|

| Factory automation | Machine frames, conveyor supports, guarding |

| R&D labs | Test rigs, modular enclosures, fixtures |

| Electronics assembly | ESD-safe workstations (with specific treatments) |

| Retail and displays | Modular stands and display frames |

| Education and hobby | Robotics frames, 3D printer bases |

T slot framing reduces build time and supports later reconfiguration. Large system houses recommend extrusions for Lean manufacturing cells and quick-change tooling.

How YouHeng’s profiles stand out

YouHeng focuses on three practical differentiators: consistent alloy quality, die maintenance for tight tolerances, and a broad accessory catalog. For international buyers, YouHeng provides metric and inch series with custom anodizing. Customers report faster assembly time and lower scrap rates when parts come from suppliers with detailed cut-to-length and machining options. For projects requiring system compatibility, YouHeng’s dimensional data sheet aligns with common T-nut and fastener families.

Choosing the right profile for a new project

- Confirm expected static loads and peak dynamic loads.

- Determine maximum unsupported span and deflection limit.

- Select series that meets stiffness and weight goals.

- Choose finish for environment and appearance.

- Decide on accessory set and cable management needs.

- Request sample cut and matching T-nut to verify fit.

Include a drawing with critical dimensions when requesting quotes. This reduces iteration and shortens lead time.

Ordering, lead times, and cost drivers

Primary cost drivers:

- Extrusion length and quantity. Longer runs lower per-unit cost.

- Alloy selection and temper. Heat treated profiles cost more.

- Surface finish. Anodize and powder coat add per-meter cost.

- Machining services. Holes, slots, and milling add time and cost.

- Custom dies. New profile shapes require tooling charges.

Standard stocked lengths reduce lead time. Custom profile dies take weeks to produce; when budget permits, combine several orders to amortize tooling fees. Use local distributor inventory for urgent needs.

Practical assembly tips for faster builds

- Label each cut piece before assembly.

- Use a torque-limited screwdriver for repeatable clamp force.

- Pre-load T-nuts into slots if many mates are required.

- Keep stock of commonly used connector plates to speed corner assembly.

- For on-site assembly, use a portable tramming block to guarantee square frames.

These steps reduce error rates and shorten commissioning time.

Three tables for quick reference

Table 1: Quick compatibility of common T-nuts and slot widths

| Slot width mm | Typical T-nut series | Common screw sizes used |

|---|---|---|

| 6 | M4 T-nut family | M4 machine screws |

| 8 | M5 T-nut family | M5 machine screws |

| 10 | M6 T-nut family | M6 machine screws |

| 12 | Larger profile T-nut | M8 machine screws |

Table 2: Material quick comparison

| Material | Density g/cm³ | Typical yield MPa | Best when |

|---|---|---|---|

| 6063 aluminum | 2.7 | 110–150 | Lightweight modular frames |

| 6061 aluminum | 2.7 | 150–250 | Higher strength structural parts |

| Steel | 7.8 | 250–450 | High load bearing, small footprint |

Table 3: Finish selection quick guide

| Finish | Cost impact | Maintenance need | Good for |

|---|---|---|---|

| Mill | low | low | internal frames |

| Clear anodize | medium | minimal | high hygiene areas |

| Powder coat | medium-high | periodic | colored displays |

| Hard anodize | high | minimal | wear surfaces |

Environmental handling and lifecycle

Aluminum is highly recyclable. End of life collection and recycling reduce embodied carbon. For equipment with long service life, choose durable finishes that lengthen replacement cycles. For outdoor use, PVDF or marine-grade coatings provide long term color retention.

Supplier selection: important questions to ask YouHeng or distributors

- Can you supply full material certificates and temper data?

- What is the machining tolerance for milled faces?

- Do you provide cut-to-length and kitting services?

- What is MOQ and typical lead time for standard stock sections?

- Is a custom die charge required for my profile shape?

A supplier that answers these items up front saves time during procurement. Many customers prefer vendors that include a small sample kit for fit verification.

Common mistakes and how to avoid them

- Wrong slot dimensional match: always test a T-nut sample before large orders.

- Underestimating deflection: use vendor calculators or run an FEM check.

- Using plain aluminum fasteners for high torque joints: use steel inserts where repeat assembly occurs.

- Forgetting cable paths: add internal cable channels early in the design.

A short pilot build reduces costly mistakes on full assemblies.

Five frequently asked questions with answers

Q1: What is the most common alloy for T slot profiles and why?

A1: The most common alloy is 6063 since it extrudes cleanly, provides a smooth surface for anodizing, and balances strength with low cost. For higher mechanical demands, 6061 is an alternative.

Q2: How do I choose between 20 series and 40 series profiles?

A2: Use 20 series for lightweight frames and small fixtures. Use 40 series when bending stiffness or load capacity is required. If unknown, pick the larger series then optimize.

Q3: Can T slot frames handle dynamic loads and vibrations?

A3: Yes when designed with appropriate bracing and joint geometry. For high vibration, add gussets and consider bolted steel inserts at repetitive joints.

Q4: What surface finish should I select for cleanroom equipment?

A4: Clear anodize with a specified oxide thickness works well for corrosion resistance and cleaning. Consult for ESD treatment if required.

Q5: Are custom profiles possible and what is the lead time?

A5: Custom profiles are possible but require a die. Lead times vary; tooling can take multiple weeks. Combine orders to recover tooling cost.

Final checklist before production

- Verify load calculations or request structural review.

- Order samples for slot and fastener fit.

- Lock finish and length tolerances in the purchase order.

- Ask for kitting services to reduce on-site work.

- Confirm certification and traceability paperwork.

Closing note

YouHeng’s T slot aluminum extrusion profiles offer a modular, lightweight, and durable platform for modern manufacturing and product support. Proper selection of series, alloy, finish, and accessories leads to systems that save time and cut lifecycle cost. For project support, YouHeng provides dimensional data sheets, sample kits, and cut-to-length services to accelerate deployment. For technical backup, consult product datasheets or speak with an applications engineer to validate your design.